"You have to drive yourself to get ahead"

Follow Fahd on his journey from a Chemical Engineer to a Senior Business Manager

When you think of a chemical engineer working in a production plant, you're not quite wrong, but you're also not quite right: Fahd Taie, Senior Business Manager, has a long career behind him and many plans for the future.

"A good sales manager ideally has a technical background. He is the link between customer, production and marketing", says Fahd and sums it up: "Use your knowledge and experience from different areas to build trust and fulfil your customer needs.”

After his studies at the University of Cairo, he saw his professional future in a production plant. And indeed, as a technical support engineer, he started his career in a simulation and modeling company for the oil and gas plants. "You have to drive yourself to get ahead," says Fahd. He expanded his experience and joined a multinational chemical company till he became Technical Sales Manager until 2008. Immediately after, Fahd decided to take another challenge and joined Evonik's office in Cairo, as regional marketing manager responsible for the Middle East/ Africa region for SiYProTM (Simplify your Process) product group for the petrochemicals industry. The product group consists of additives that reduce fouling formation in the production of vinyl monomers and thus increase plant throughput. During his completion of his MBA (Master of Business Administration), He got the opportunity to join Evonik team in Germany in 2012 to add another milestone to his experience and career path.

Fahd has just adopted a new additional topic and says: "Evonik is always offering you new opportunities and giving you access to knowledge. Different cultures and different professional environments shape you as a person and turn your career into a journey on which there is always something to discover that makes you better".

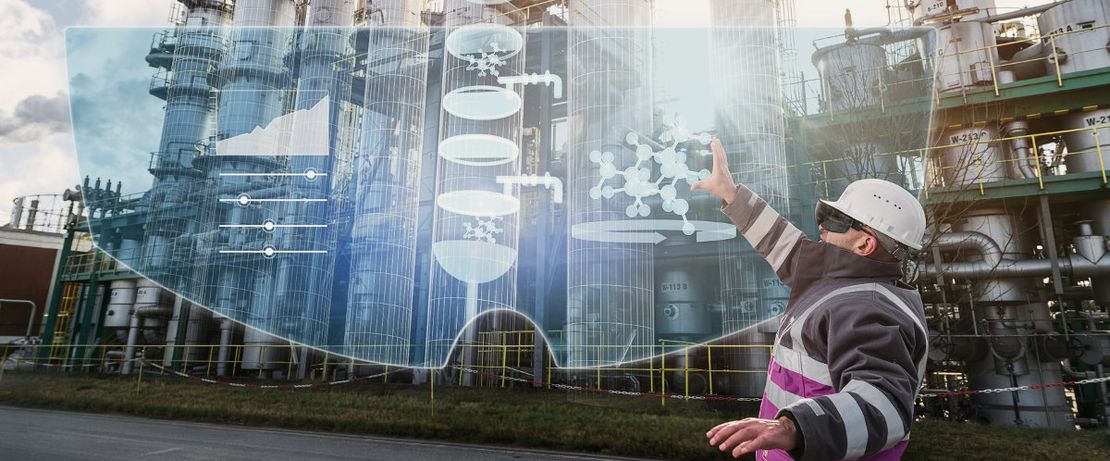

Fahd works at the Marl Chemical Park, one of the largest chemical sites in Germany and Evonik's largest production site. The site covers an area of more than six square kilometers and provides around 10,000 jobs. The focus of production at the Marl Chemical Park is on converting petrochemical raw materials such as benzene, ethylene, propylene, methanol and phenol into basic, fine and specialty chemicals - from C4 cut to downstream products, from chlorine electrolysis to PVC, from acetylene to tetrahydrofuran, from fatty alcohols and ethylene oxide to surfactants, and from acrylic acid to butyl acrylate.